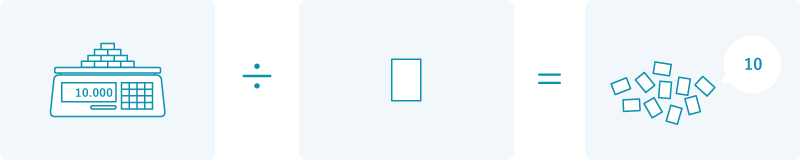

Quantity verification involves confirming that the number of items matches the specified amount.

The term "quantity" refers to the count of items or people, indicating a predetermined total. Depending on the industry or company, it may also be called quantity check, quantity inspection, quantity counting, or quantity management, but all terms share the same meaning.

Quantity Verification Scenarios

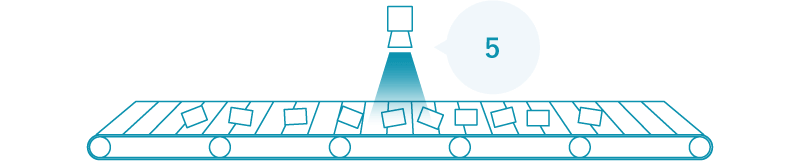

- Checking whether the received quantity matches the specified amount in the work instruction from the previous process.

- Confirming that all necessary components are present in the assembly process of manufacturing.

- Counting defective items when the incoming and outgoing quantities should be the same.

- Verifying that the required number of items fit into the designated case.