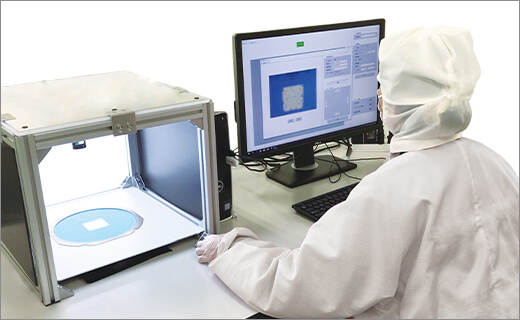

Instant Counting of Components with Image Processing

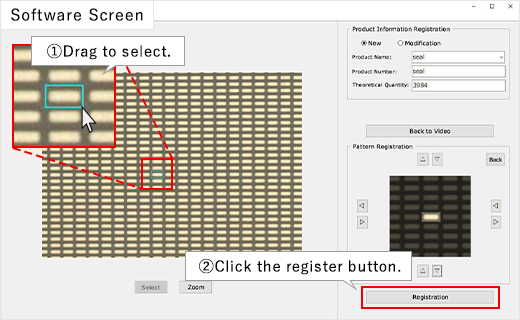

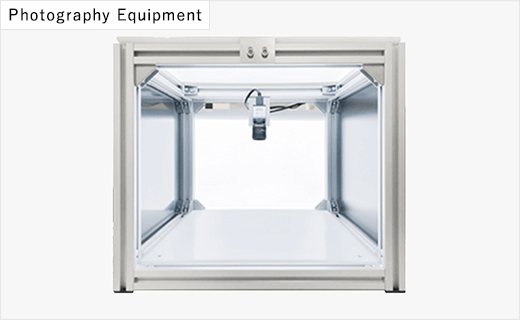

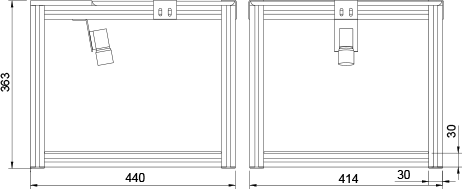

The Counter SD-1000 is a device that uses proprietary image processing technology to count components.

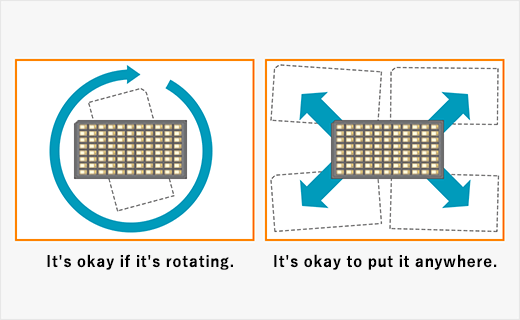

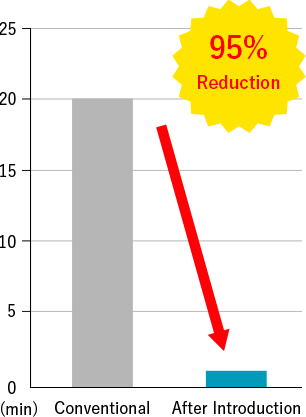

It captures images of components using a camera and displays the total detected count on a monitor. It automates component counting and quantity verification tasks performed during product receiving and shipping. Even small and lightweight components, which are difficult to count using conventional methods like weight measurement counters or drop counters, can be counted accurately.