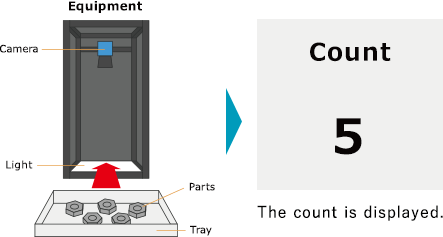

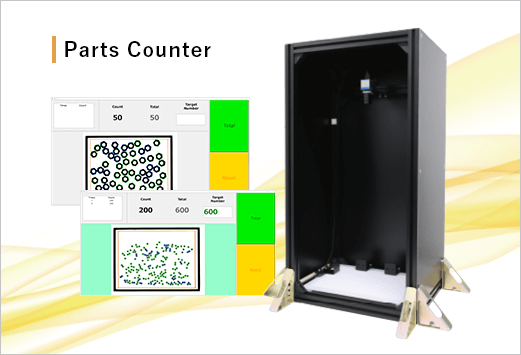

Instant Real-Time Counting of Loose Parts

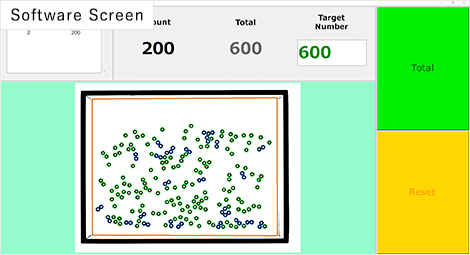

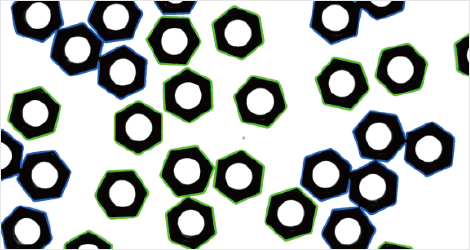

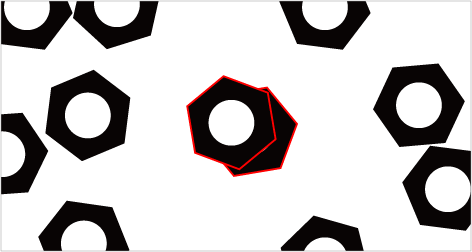

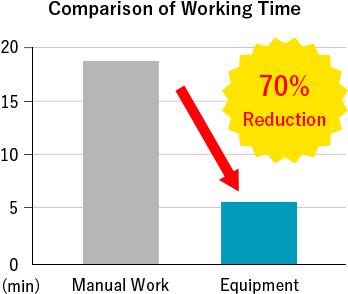

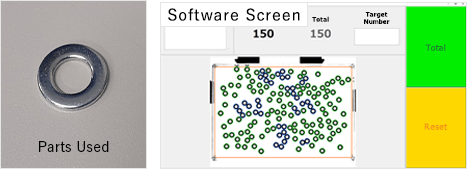

This software instantly counts the number of scattered components within the camera's field of view. With proprietary contour feature analysis, there is no need for tedious product registration—simply place the components under the camera to start counting. By setting a target count, the accumulated results can be tracked, making it useful for verifying component quantities during small-lot packaging.

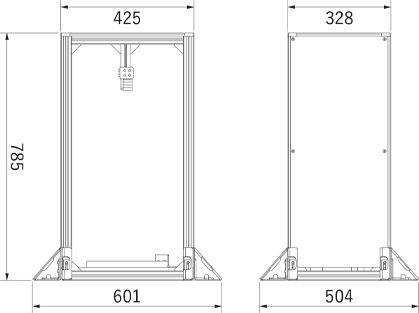

※ Manufactured by SAITOH Co., Ltd.